Silicon Moulds

It is one of the most famous and known procedures used in rapidly making flexible moulds guaranteeing reproduction of a limited number of details (5 to 50), from a material close to the final one : which is meant for first functional testing . The equipment is made of silicon flexible resin ; which allows one to slash : management, material , and workforce costs ; as well as reducing implementation times.

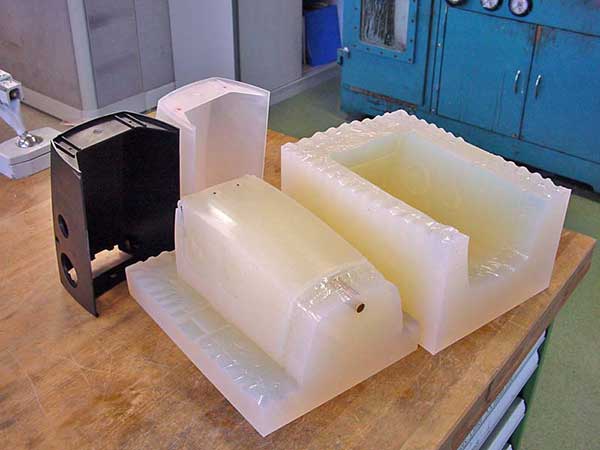

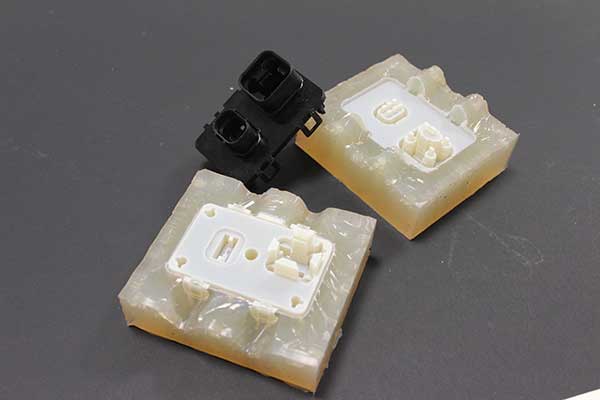

To make the rubber mould one starts with a first prototype (Master), and adds air-vents and runners, and arranges the parting line . All items are placed in the containment box: into which previously degassed resin is injected at atmospheric pressure .This is followed by a second degassing phase : in order to remove air trapped during injection moulding ; subsequently the mould is placed in the oven for hardening . Thanks to the translucent rubber employed : one can locate the parting line ; as well as making a cut with irregular edges : in order to achieve perfect coupling afterwards, with a simple insert . Therefore one can make flexible and self-detaching moulds : in order to accurately reproduce details, which may well be complex .